What are AkzoNobel Yacht’s future development plans for antifoulings with reduced environmental impact?

Prior to commencing any new development in the Research & Development laboratories within AkzoNobel Yacht, there are several assessments and programs in place that ensure that each and every new antifouling is fully compliant with a stringent set of internal policies designed to assess the potential impact of any new project.

These include carrying out a full environmental risk assessment integrated into the product development plan; Use of approved non-persistent biocides [those which degrade / detoxify when they enter the environment]; Optimizing biocide levels to ensure products which release minimal amounts of biocide [to be effective] and active research / development programs that develop efficient but greener antifouling products.

The majority of the antifouling research carried out by Akzo Nobel Yacht takes place in the Marine and Protective Coatings (M&PC) Technology Centre in Newcastle, in the North East of England.

This team of pioneering scientists works closely with the Yacht development laboratories world-wide, and is housed in a state-of-the-art research facility which opened in 2007. Responsible for researching into new coating technologies for use across the business, key areas of research include: antifoulings, chemical and heat resistant coatings, color/pigment dispersion, fire protection and materials/corrosion science.

A significant proportion of the work carried out within the Technology Centre (TC) is focused towards research into new solutions to the biofouling problem. Biofouling is the complex natural process whereby surfaces immersed in the marine environment become colonized by organisms. The negative consequences of fouling and the benefits of a clean hull have been recognised for millennia, as reported by Plutarch in the first century A.D.

“(A vessel) glides lightly, and as long as it is clean, easily cuts the waves; but when it is thoroughly soaked, when weeds, ooze, and filth stick upon its sides, the stroke of the ship is more obtuse and weak; and the water, coming upon this clammy matter, doth not so easily part from it; and this is the reason why they usually scrape the sides of their ships.”

In comparison to this timescale, AkzoNobel Yacht has only been focused on solving the fouling problem for a relatively short period of time! However, throughout its history – spanning over 100 years of paint-making – International has been at the forefront of breakthroughs in antifouling technology.

The key driver for antifouling research is now environmental; both in reducing the impact of biocidal products and in bringing new non-biocidal technologies to market. In recent times, the main non-biocidal concept under investigation within the TC antifouling team has been based on creating a surface which reduces the adhesion strength of fouling organisms, allowing surfaces to self-clean under the weight of fouling or by water flow. Back in the 1990’s it was recognized that research into ‘foul release’ technology was being hindered by a lack of suitable test methods and limited biological knowledge as to how marine organisms interact with non-biocidal immersed surfaces. This realization has led to new methods for measuring the adhesion of marine organisms to immersed surfaces and more recently the development of in-house barnacle culturing facilities.

New methods for determining the performance of foul release coatings, coupled with studies of surface properties, such as wetting and roughness, led to the successful development of a high-performance fluoropolymer-based foul release coating. This technology, patented in 2001, combines both hydrophilic and hydrophobic surface properties, which aim to minimize the chemical and electrostatic adhesion between the surface and a wide range of fouling organisms.

In addition to the search for new fouling release technologies, research into non-fouling surfaces also continues; an area of increasing interest being the control of surface physio-chemical structure at a micro and nano scale.

The Technology Centre at International is actively involved in assessing internal and externally-derived technologies, both in conjunction with universities and European Union funded initiatives.

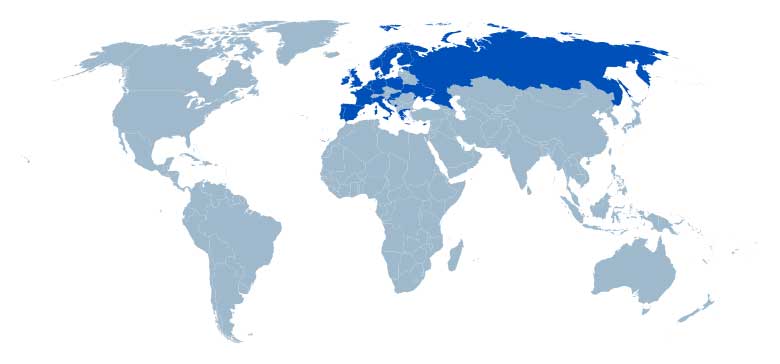

One such initiative was Project AMBIO (Advanced Nanostructured Surfaces for the control of Biofouling) an integrated program to study and develop new nano-structured surfaces for the control of biofouling in aquatic environments. This project began in 2005, with a total budget of €17.9 million, and had industrial and academic partners involved in the project from across Europe. The International Technology Centre was involved in testing candidate technologies from the AMBIO project, with a view to selecting those suitable for ‘real world’ vessel trials. Although these technologies are likely to require further development to meet commercial requirements, early involvement provided International Paint with a critical ‘head start’ towards delivering the next generation of environmentally benign antifouling coatings.

Paint your boat like a pro

Find the best products to keep your boat in great condition

Get all the support you need to paint with confidence

Benefit from our continuous innovation and scientific expertise